LatheCity.com

Tailstock Accessories Documentation

Tools:

[ Sherline ]

>

[ LASER protractor ]

> [ Mechanical protractor ]

> [ Tailstock ]

> [ Lathe/Mill Stops ]

> [ Monster Vise ]

> [ Endmill Holder ]

> [ Morse taper ]

[ Unimat ]

> [ Mechanical protractor ]

> [ Tools ]

[ China Lathe ]

[ Vintage ]

[ Craftsman ]

[ HiTorque Bench Lathe

SIEG SC2 ]

[ Learning Center ]

[ Product Tests ]

[ Freebies ]

[ How to order ]

[ FAQ ]

[ Customer Feedback ]

[ Customer Corner ]

[ Address

]

[ Contact ]

[ Returns ]

[ US shipping ]

[ International orders ]

[ Privacy ]

[ Site Map ]

[ Disclaimer ]

[ Home ]

A printed version of this documentation is included with the purchase of any tailstock accessory.

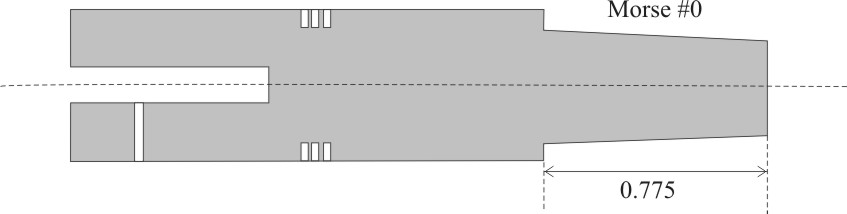

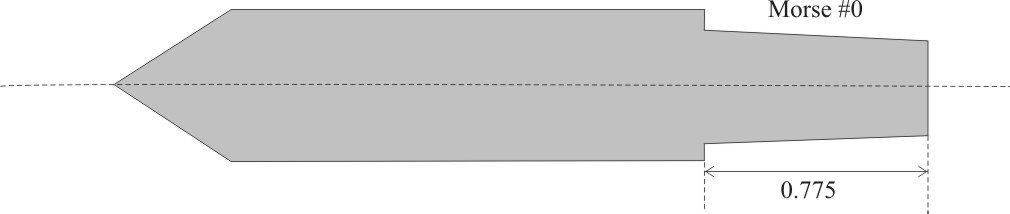

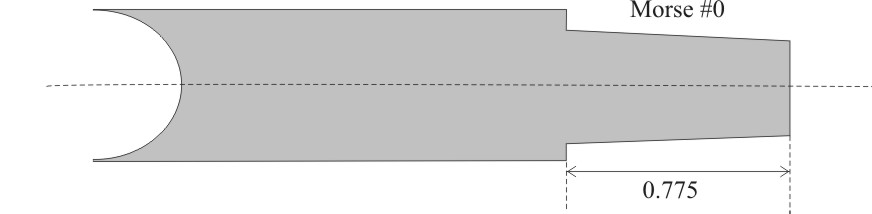

Available standard sizes Tailstock center drill holders: We do offer three adapters for #1 to #3 center drills. The adapters are long enough (~3”) to reach over a cross-slide typical for benchtop systems. The center drills (not included) are hold in place by a steel auxiliary set screw (included). You will be amazed how much time you will save using these snap-on adapters for center drills. Morse #0 taper – extended dead center. The accessories have a Morse #0 taper at one end and a 30° pin (taper) at the other end. The steel pieces can be used as a dead center. The adapters are long enough (~3”) to reach over a cross-slide typical for benchtop systems (replacing an expensive Morse arbor – taper adapter). These pieces are cut from (non-hardened) steel, but the pin end may wear out over time (as usual use cutting oil when using dead centers). However, any (hobby) machinist can easily resharpen the pin end by cutting e.g. a 30° taper. (When working mostly with aluminum, we have used these pieces for a year without significant sign of wear.) We do also offer an extended dead center with a concave end which is useful when turning odd shaped pieces.

Procedure: Extend the tailstock spindle by about ¼”. For best fit, slightly (and carefully) slam the taper adapter in the spindle by hand. To remove the taper, pull back the spindle. Typically taper arbors/spindles have an internal draw bar which will push out the taper. Safety notes and disclaimer: General safety rules for machine tools are in place. For an extended list of safety notes consult the literature. One can download free of charge a safety booklet which is also typically included for first time customers (free of charge). Returns in resalable conditions are accepted within 30 days after shipment. All shipping costs will be covered by the customer. No restocking fees, no questions asked. No returns of custom designs or customized designs. General sells and business terms are active. Please note the length and end style of Morse taper varies, depending on application and lathe model. Our version is tailored towards small benchtop lathes. A Morse #0 taper has a larger end with O.D. of 0.3561”. The standard version we offer has a taper length of 0.775” for short benchtop tailstock spindles. Other sizes are available on request as custom designs. Typically LatheCity accessories are made from aluminum (Al), unless otherwise noted, which keeps the prices low and is durable enough. In addition, the aluminum adapters guarantee not to damage e.g. threads. Looking at rusting pieces made by other vendors out of “stainless” steel ... Well, this does also not happen with aluminum adapters. |